Hello, Blog readers!

Today, we will aboard a topic that must be considered in a casting process, in order to mantain the final piece always fulfilled, therefore avoiding empty spaces:

shrinkage.

|

Picture 1. Solidification process, ranging from the liquid (to the left) to the solid (to the right) state progressively, demonstrating the shrinkage phenomena.

Source: CÂNDIDO. Aula de Materiais.

UNISINOS. Rio Grande do Sul. Available at:

<http://s3.amazonaws.com/magoo/ABAAAAbGIAH-1.jpg>. Accessed at: 27

de nov. 2015. |

As Cândido writes, "a metal solidification starts by the parts which are in contact with the mold walls or the superior part, where the metal is in air exposure. The metal, passing through the liquid state to the solid shrinks its volume, therefore a central region in the ingot or piece will show up, called shrinkage". The phenomena can be observed accordingly to Picture 1 above. Considering the lost volume when contracted, the shrinkage is the difference between the liquid and solid volumes (respectively, initial and final).

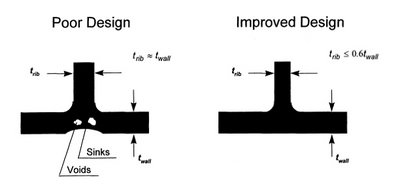

Its importance during the Integrator Project can be relevated in the last week's posting, where there was the need to computate its volume. For projects that involve metal foundry, its volumetric contraption must be considered. Otherwise, the final result is different from the desired one, creating defects, accordingly to Picture 2.

|

Picture 2. Cast comparison. To the left, with many voids (empty spaces) and sinks (macroporosities), altogether with the shrinkage. To the right, a picture of an adapted mould for these problems.

Source: TECNOLOGÍA INDUSTRIAL

UNIVERSIDAD MAYOR. Rechupe - Contracción. Tecnología Industrial Universidad

Mayor, 2006. Available at: <http://tec-ind-umayor.blogspot.com.br/>. Accessed at: 27 nov. 2015. |

In the industry, it's important the volumetric contraction consideration. Therefore, many times (and including the Project Integrator's case) it is used a molten metal feeder. Crystalizing slower than the mould material, it guarantees entire piece fulfillment. The "massalote", as it is commonly called in Brazil, is cut off and discarded/recycled afterwards.

That's everything for the week, folks!

Best regards,

Solarium Engineering Team

Nenhum comentário:

Postar um comentário